Whisker Inspection

Whiskers are microscopic metallic filaments that grow from the surfaces of many metals; tin, zinc and silver being the most common hosts. Whiskers can grow long enough to reach adjacent components, leads, or lands, and as they are conductive they can cause electrical shorts. Elmet routinely performs both optical and SEM examination for whiskers. Energy dispersive spectroscopy (EDS, or EDAX) is used to verify the elemental content of whiskers. We often work to customer provided specifications, but we also work to industry specifications such as JESD22-A121A.

Tin whisker inspections

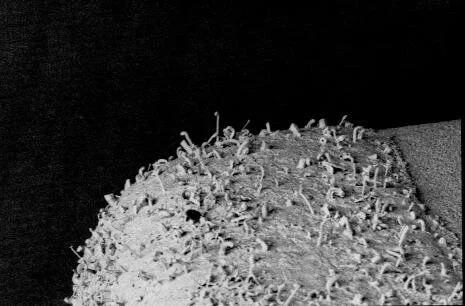

Capacitor with nodules and whiskers. Image credit to NASA. Banner image credit to NASA.

Description of Tin whiskers and INspections

Whiskers are microscopic metallic filaments that grow from the surfaces of many metals; tin, zinc and silver being the most common hosts. Whiskers can grow long enough to reach adjacent components, leads, or lands, and as they are conductive they can cause electrical shorts. The aerospace industry has been aware of whisker formation since the 1970s. Since then the automotive and other manufacturing industries have strived to test for, and control, this phenomenon. The inspection method generally involves a relatively high (20x-100x) magnification visual inspection with an optical microscope. Higher magnification inspections (into the thousands) generally need to be done in a scanning electron microscope (SEM). Inspections may focus on specific components with susceptible coatings or closely pitched leads, or may cover a whole board.

Elmet routinely performs both optical and SEM examination for whiskers. Energy dispersive spectroscopy (EDS, or EDAX) is used to verify the elemental content of whiskers. We often work to customer provided specifications, but we also work to industry specifications such as JESD22-A121A.

High magnification whisker. Image credit to NASA.

Deliverables

Elmet will supply overview and high magnification photographs of inspection targets. Additional photographs, electron micrographs or EDS spectra (see SEM Services) are delivered based upon the scope of the inspection. The photographs and findings are organized into a written report along with a summary of observations. CLICK HERE for an example report.

What to do next

We need to know certain things to quote and provide you with a whisker inspection.

We need to know the specifications you want us to work to. JEDEC/JESD22-A121A is a common industry standard, and many automakers have their own specifications or requirements (GMW3172 from GM or TSC7038G from Toyota). Do you need whiskers measured? Counted? Or a simple yes or no statement as to their presence? Do you need a full board inspection or only certain targeted components? In the latter case, most customers provide a layout or photograph of the circuit board with the target components marked. The photograph below shows an example.

Example board with marked inspection targets. These components were selected for inspection because of the close lead spacing.

We also need to know how many circuit boards you want evaluated, and we need to know if they are all arriving simultaneously or if some arrive this month and more next month.

We need a specific scope of work. This could be simple, such as inspect for whiskers, or it can be more detailed, such as inspect the board per JESD22-A121A, followed by EDS analysis of any located whisker, and a length measurement of the longest whisker on each board.

Call or email us with any questions that you have about the process, our capabilities, delivery, or price. Or, you can submit the layout and scope of work and we’ll get back to you with a quote. Or, visit our Price Estimation form if you want a fast, informal idea as to scope of your project!